Scientific goal

In the last decades, civil engineering sector in the Central Europe has been experiencing an increase in utilizing natural materials for a construction of both family and multi-storey buildings. Among these materials, the wood plays the most significant role due to its advantageous mechanical and thermal properties with respect to its weight, and due to its environmental friendliness. Due to environmental concerns and climate changes, the forest composition is currently changing towards broadleaved species among which European beech (Fagus sp.) will play significant role in future. However, to utilize any wood in a construction, one is obliged to use connections to provide needed structural dimensions and spans, especially when using cross-laminated timber (CLT), glued laminated timber (GLT). Adhesive bond is the most frequent connection to form wood composite materials (WBC’s) and it also plays significant role in performance of the whole material, especially from a long-term perspective during ageing. Long-term service life means that wood for indoor/outdoor exposures face unfavorable conditions causing undesired phenomena such as weathering, fatigue or delaminations at adhesive bond. The exposure is represented by a combination of periodic hygro-thermo-mechanical loads that vary based on season, week day, precipitation rate, wind rate, sun shine, using air-conditioning, location etc. These natural and human-caused conditions heavily impact performance of all timber structures, but especially bridges, towers, tall-timber buildings, lookout towers etc. The loads do not impact only wood material itself, but also the adhesive bond that binds wooden parts together. To extend the durability of adhesive bond and to predict its service life or failure, the complex understanding of its behavior with respect to climate conditions has to be provided. To achieve these goals, new approaches and techniques are necessary to be used to obtain higher quality bondline from the complex loading point of view. The prediction and diagnostics models would help to lower production costs of glued timber structures due to detailed knowledge of their behavior as well as in-time treatments of restorations when their service is negatively impacted [1].

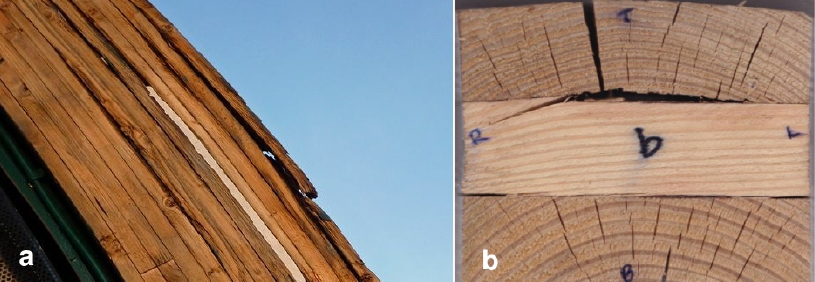

Figure 1: Extreme case of adhesive bond delamination of GLT: a) caused by a natural weathering (Source:

https://failuremechanisms.files.wordpress.com/) and b) caused by an accelerated weathering [22].

Despite the proportion of the timber structures is increasing in the Central Europe, there is a big lack of knowledge about an impact of complex loads on a performance of bond between beech wood and adhesive. This project aims on addressing this call and knowledge gap by carrying out the extensive research on that topic, including the impact of ageing on rigid and flexible adhesive bond in beech to be used in timber constructions. The research will be based on three pillars: extensive experimental testing, numerical modeling and big data analysis, all synergically carried out by four teams in the project consortium – Tadeusz Kościuszko Cracow University of Technology (Poland), AGH University of Science and Technology (Poland), InnoRenew CoE (Slovenia), Slovenian National Building and Civil Engineering Institute (Slovenia). The project will provide fundamental knowledge and models for a prediction and diagnostics of rigid and flexible adhesive bonds made with beech wood. Impact of the project can be seen in obtaining fundamental knowledge in adhesion science, wood science, mechanics and physics of materials.

Significance of the project & State-of-the-art

Mechanical performance

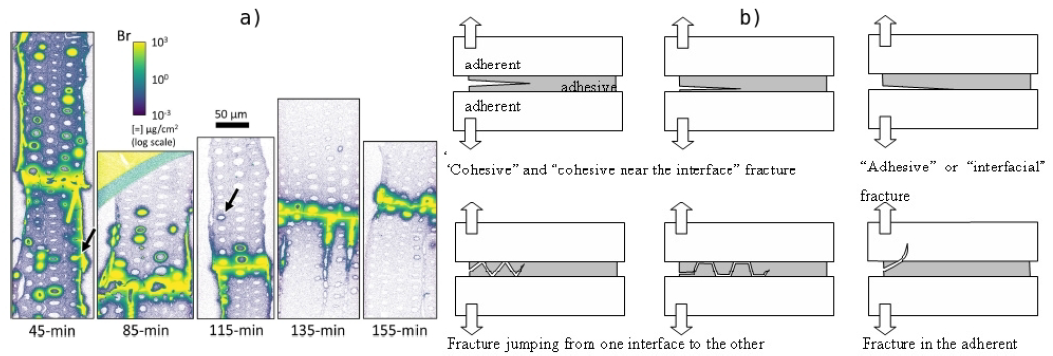

For a production of high-performance WBC’s, a fundamental understanding of adhesive bond behavior and properties is essential [2]. Mechanical tests of adhesive materials are usually made on a macroscopic scale, but micro- and nanoscopic investigations bring important findings about micromechanics and penetration of adhesive into wood when coupled with X-ray μCT or X-ray fluorescent microscopy, see Figure 2a [3, 4]. Adhesive-wood complex is a very complicated mechanical system where many local events such as non-uniform cracking in adherend/adhesive occur when exceeding bearing capacity (see Figure 2b), and, therefore, use of a full-field technique such as digital image correlation (DIC) is advantageous when analyzing strains and crack openings around the bond area [5, 6]. The performance and quality of adhesive bonds is usually tested using tensile lap shear tests, tension test perpendicular to adhesive bond and delamination tests according to EN 16351 [7]. Important factor for performance of PVAc adhesive bond was found the feeding rate [8]. Adhesives differ, but in quasi-static and fatigue failure tensile shear loading, PUR and MUF showed similar strengths, with majority of glue failure for PUR and wood failure for MUF [9]. Also the orientation of plywood surface layer shows to have minor influence on the shear and tensile strength of edge-to-surface joint [10]. The bond strength of beech glued by different adhesives (PVAc, MUF, PRF, PUR) showed that failure mode in standard lap joint tests was mainly wood failure [11].

Figure 2: (a) Penetration of adhesive evaluated by X-ray fruorescent microscopy (from [4]); (b) complex fracture phenomena occurring during delamination of the wood-adhesive bond that calls for using X-ray μCT, full-field and numerical ] approaches.

In addition to tests providing strengths and elastic parameters, adhesive bonds need to be examined in fracture perspective – crack onset and propagation via the adhesive bond. Fracture properties of beech glued with PUR, PVAc and MUF and in different climate conditions in mode I showed that ageing increase probability of delamination and failure [12]. Testing PRF and PUR adhesive showed that there is no difference between PRF adhesive bond and wood itself in terms of strain energy release rate (GI), but there is a statistical difference for PUR [13]. It was found out that GI at maximal force is a good estimation of GIc critical value [14]. Further, it was showed that for epoxy adhesive bond, its thickness strongly influences the measured value of GI, which was also confirmed by finite element (FE) models [15]. Fracture properties in mode II can be tested using Arcan test or three-point end-notched flexure test (3ENF), conveniently joined with DIC [16]. On the other hand, obtaining GII without DIC is possible too and it showed that performance of PRF and PUR adhesive bonds is similar under quasi-static loading [17]. Bonds of beech with PUR adhesives are more difficult to assess using 3ENF since greater strain at failure allows to develop plastic strain in wood first before cracking in bondline [18].

Ageing and accelerated weathering

Adhesive bond experiences ageing based on doses of UV, mechanical loads, relative humidity and temperature cycles (RH-T cycles), which impacts its behavior, appearance and mechanical performance, depending on species, adhesive type and weathering regime. However, some study showed that for PRF and MDI, the weathering effect might not bring statistical difference in adhesive failure load compared to control samples [19]. On the other hand, it was also showed the wood-adhesive bonds using PUR and PRF are highly affected by weathering regime and growth region within the tree diameter [20]. It seems that most of the decrease in mechanical performance of PUR adhesive bond can be explained by a reduction in properties of wood itself, rather than of the adhesive film [21]. With respect to a weathering and delamination, micronized copper azole type C (MCA-C) for treating CLT glued with PUR against biodegradation and delamination shows to be very promissing technique [22].

Acoustic characterization & dynamic diagnostics

Vibro-acoustic methods are nondestructive diagnostic methods that have been largely applied for structural health monitoring of buildings, with a special focus on tall timber constructions [23]. The use of acoustic emission (AE) method is based detecting discrete burst signals generated inside the structural elements, such as micro-cracking and is a primarily used for real-time damage monitoring [24]. An experimental modal analysis on which basis 420 solid wood beams and GLT beams have been evaluated showed the total amount of damping is similar for both beam types, but GLT beams generally has smaller variation of damping [25]. Damping and other modal parameters can be determined in dynamic diagnostics of stiff and flexible adhesives using a non invasive modal hammer method [25a]. Also the artificial-intelligence (AI) based classification approach can be used to detect the presence of insects in wood [26]. Material degradation such as localized failure, cracking or fracture propagation, releases an internal strain energy, that can be detected as a propagating elastic waves – acoustic emission (AE). AE offers an in-situ, high sensitivity monitoring for early detection of evolving defects and within modern layer structure of various WBC’s and was successfully applied on hard wood species [24, 27]. Distinction of AE signals can be related to different adhesive bondline failure mechanisms [28] and detection with identification of crack tip while monitoring the propagation of crack in wooden specimens, loaded under stress [29].

NIR & Hyperspectral approaches & Multivariate techniques

Diverse industrial scanners become integral part of advanced manufacturing solutions in wood industry, usually based on an interaction of the electromagnetic waves with wood [30]. Among those, near-infrared spectroscopy (NIR) is promising technology because the analysis of NIR spectra allows prediction of various chemical-physical traits of the scanned object, recorded in the spectrum as a wavelength-dependent light absorbance and scatter. An extension of “classical” NIR spectroscopy is hyperspectral imaging (HI) providing additional dimensions (2D space) which is very suitable for analysis of heterogonous materials such as wood [31]. A successful implementations of NIR and HI for the determination of diverse wood properties was reported [32]. Portable and low cost spectrometers were also successfully utilized for detection of diverse wood defects [33]. The biggest challenge when implementing NIR/HI-based solutions in the real-world applications is impossibility for the direct interpretation of the spectra. For that reason a variety of chemometric methods was proposed to analyze the spectra considering it as a multivariate data set. A new research field was born in this regard, namely Big Data analytics and machine learning approaches. There is a very broad range of different algorithms suitable to extract the knowledge from such enormous data sets. Very same solutions can be also applied for wood characterization as well as for revolutionizing the quality assurance of bondline, which is an integral part of the proposed project.

PUR adhesives at elevated temperatures

Strength and stiffness of adhesives decrease with temperature increase usually in the range of 20-80°C (lower than the fire) [34,35], causing changes in wood-adhesive bondline behaviour. This decrease is related to the phenomenon of glass transition Tg, characteristic for polymeric materials. The glass transition temperature Tg of polymers strongly depends on the type of adhesive, its formulation (rigid or flexible), thermal history and age [36] and can be determined for raw materials by differential scanning calorimetry (DSC), differential thermal analysis (DTA) or dynamic mechanical analysis (DMA).Testing of wood-adhesive bondline performance and quality at elevated temperatures, using tensile lap shear tests and compression tests of double shear lap was reported in [37].

Project concept and goals

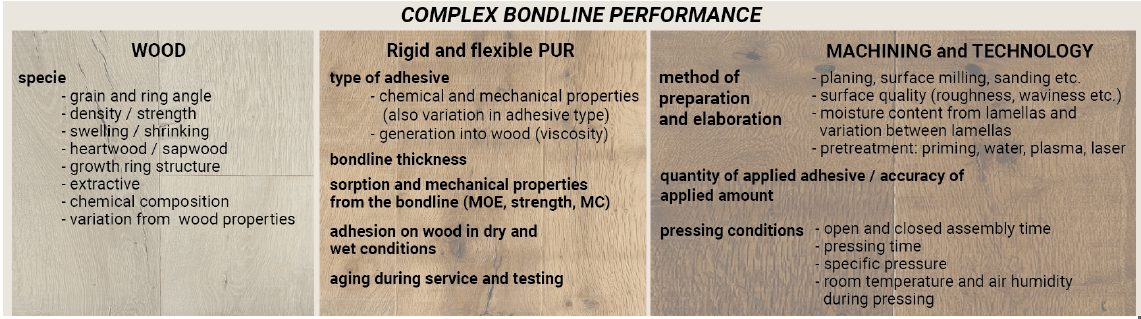

The project main idea is based on two main aspects: (i) an importance of learning whether aging of rigid and flexible beech-adhesive bondline used in timber structures causes changes of its physical performance; (ii) in the Central Europe there are many complementary teams and facilities that may bring novel knowledge via more tight cooperation despite the country borders. Since the adhesive bond experiences a very complex physical loading consisting of short, dynamic, long-term effects coupled with influences of water absorption, and contains many variables of input materials (see Fig. 3) it requires very robust experimental design. Joining four teams in the Central Europe region provides a very strong platform to solve outlined challenges.

Fig. 3 Complexity of bondline performance with respect to a quality of input materials and technology.

Due to climatic changes, future forests will consist of great amount of broadleaved species such as beech, which is a quite problematic and very unknown species with respect to adhesive joining and its use in timber constructions. The desired service life of such structures can be only assured by knowledge of adhesive bond performance over life span of the building. The proposed research addresses it by utilizing the robust experiment design with aging of the rigid and flexible bonds made of polyurethane (PU) adhesives, considering rigid polyurethanes (RPU) made of PUR and flexible polyurethanes (FPU) made of several polyurethanes of type P with various flexibility levels. Therefore, the overall project goals are:

- To evaluate properties of beech-adhesive bond with PUR/FPU prior and after accelerated and natural weathering (ANW).

- To investigate the effect of spatial distribution of PUR/FPU adhesive and its microstructure incorporation on behavior of adhesive bondline after ANW.

- To evaluate quasi-static, fatigue, fracture and dynamic mechanical properties and behavior of beech-adhesive bondlines prior and after ANW.

- To develop relationships between material quality and technological parameters during bonding on complex mechanical performance of beech-adhesive bondline using multisensor approach and multivariate techniques

- To find out whether vibro-acoustic techniques may be utilized to diagnose the damage of the adhesive bondline.

- To examine an effect of elevated temperatures on beech-adhesive bondlines

- To comprehend findings for a development of theoretical and analytical prediction models of adhesive bonds, its damage and its diagnostics incl. life cycle.

Project literature

1. Vallée T, Tannert T, Fecht S (2017) Adhesively bonded connections in the context of timber engineering – A Review, The Journal of Adhesion, 93(4):257-287.

2. Stoeckel F, Konnerth J, Gindl-Altmutter W (2013) Mechanical properties of adhesives for bonding wood—A review. Int. Jour. Adhesion & Adhesives 45:32-41

3. McKinley P, Kamke FA, Sinha A, De Andrade V, Jakes JE (2018) Analysis of Adhesive Penetration into Wood using Nano-Xray Computed Tomography. Wood Fiber Science 50(1):66-76

4. Jakes JE, Frihart CR, Hunt CG, Yelle DJ, Plaza NZ, Lorenz L, Grigsby W, Ching DJ, Kamke F et al. (2019) X-ray methods to observe and quantify adhesive penetration into wood. Journal of Materials Science 54(1):705-718.

5. Brault R, Germaneau A, Dupre JC, Doumalin P et al. (2013) In-situ Analysis of Laminated Composite Materials by X-ray Micro-Computed Tomography and Digital Volume Correlation. Experimental Mechanics 53(7):1143-1151.

6. McKinley P, Sinha A, Kamke FA (2019) Understanding the effect of weathering on adhesive bonds for wood composites using digital image correlation (DIC). Holzforschung 73 (2):155-164

7. EN302 1-4, Adhesives for load-bearing timber structures test methods; 2004.

8. Biazzon et al. (2019) Shear Strength of Eucalyptus saligna Wood Joints Bonded with Polyvinyl Acetate Adhesive. Bioresources 14(2):4590-4602.

9. Bachtiar EV, Clerc G, Brunner AJ, Kaliske M, Niemz P (2017) Static and dynamic tensile shear test of glued lap wooden joint with four different types of adhesives. Holzforschung 71(5):391-396.

10. Frolovs G., Rocens, K., Sliseris, J. (2017) Shear and tensile strength of narrow glued joint depending on the grain direction of plywood plies. Procedia Engineering 172 :292 – 299.

11. Konnerth J, Gindl W, Harm M, Muller U (2006) Comparing dry bond strength of spruce and beech wood glued with different adhesives by means of scarf- and lap joint testing method. Holz als Roh- und Werkstoff 64: 269–271.

12. Watson P, Clauss S, Ammann S, Niemz P (2013) Fracture properties of adhesive joints under mechanical stresses. W. R. 58:43-56.

13. Ammann S, Niemz P (2015) Specific fracture energy at glue joints in European beech wood. I. J. Ad. & Adh. 60:47–53.

14. Xavier J, Fernandes JRA, Frazão O, Morais JJL (2015) Measuring mode I cohesive law of wood bonded joints based on digital image correlation and fibre Bragg grating sensors. Composite Structure 121:83-89.

15. Han X, Jin Y, Da Silva L et al. (2019) On the effect of adhesive thickness on mode I fracture energy – an experimental and modelling study using a trapezoidal. Jour. Adh. DOI:10.1080/00218464.2019.1601087

16. Murata K, Bachtiar E, Niemz P (2017) Determination of mode I and mode II fracture toughness of walnut and cherry in TR and RT crack propagation system by the Arcan test. Holzforschung 71(12):985-990.

17. Clerc G, Brunner A, Josset S, Niemz P, Pichelin F, Van de Kuilen JWG (2019) Adhesive wood joints under quasi-static and cyclic fatigue fracture Mode II loads. International Journal of Fatigue 123:40-52

18. Sebera V, Pečnik JG, Azinovič B, Milch J, Huč S. Wood-Adhesive Bond Loaded in Mode II: Experimental and Numerical Analysis Using Elasto-Plastic and Fracture Mechanics Models. Holzforschung 75 (7), 655-667.

19. McKinley P, Sinha A, Kamke FA (2019) Understanding the effect of weathering on adhesive bonds for wood composites using digital image correlation (DIC). Holzforschung 73 (2):155-164.

20. Mirabile KV, Zink-Sharp A (2017) Fundamental Bonding Properties of Douglas-Fir and Southern Yellow P.Wood. FPJ 67:435-447.

21. Clerc G, Brülisauer M, Affolter S, Volkmera T, Pichelina F, Niemz P (2017) Characterization of the ageing process of onecomponent polyurethane moisture curing wood adhesive. Int. J. Ad. & Adhes. 72:130-138.

22. Lim H, Tripathi S, Tang JD (2020) Bonding performance of adhesive systems for cross-laminated timber treated with micronized copper azole type C (MCA-C). Construction and Building Materials 232:117208

23. Riggio, M. and Dilmaghani, M. (2020) ‘Structural health monitoring of timber buildings: a literature survey’, Building Research & Information, 48(8), pp. 817–837. doi: 10.1080/09613218.2019.1681253.

24. Palma, P. and Steiger, R. (2020) ‘Structural health monitoring of timber structures – Review of available methods and case studies’, Construction and Building Materials, 248, p. 118528. doi: 10.1016/j.conbuildmat.2020.118528.

25. Labonnote, N., Rønnquist, A. and Malo, K. A. (2013) ‘Experimental evaluations of material damping in timber beams of structural dimensions’, Wood Science and Technology, 47(5), pp. 1033–1050.

26. Bilski, P. et al. (2017) ‘Detection of Wood Boring Insects’ Larvae Based on the Acoustic Signal Analysis and the Artificial Intelligence Algorithm’, Archives of Acoustics, 42(1), pp. 61–70. doi: 10.1515/aoa-2017-0007.

27. Perrin M, Yahyaoui I, Gong X (2019) Acoustic monitoring of timber structures: Influence of wood species under bending loading. Constr Build Mater 208:125–134. doi: 10.1016/j.conbuildmat.2019.02.175

28. Clerc G et al. (2019) Fractography combined with unsupervised pattern recognition of acoustic emission signals for a better understanding of crack propagation in adhesively bonded wood. W. Sci Tech 53:1235-1253.

29. Diakhate M, Angellier N, Moutou Pitti R, Dubois F (2017a) On the crack tip propagation monitoring within wood material: Cluster analysis of acoustic emission data compared with numerical modelling. Con B. Mat 156:911-920.

30. Schimleck LR, Raymond CA, Beadle CL, Downes GM, Kube PD and French J (2000) Applications of NIR spectroscopy to forest research. Appita Journal 53: 458–464

31. Leblon B, Adedipe O, Hans G, Haddadi A, et al. (2013) A review of near-infrared spectroscopy for monitoring moisture content and density of solid wood. The Forestry Chronicle. 89(05): 595-606.

32. Sandak J, Sandak A, Meder R (2016) Assessing trees, wood and derived products with NIR spectroscopy: hints and tips. Journal of Near Infrared Spectroscopy, vol. 24, no. 6, pp. 485–505a

33. Sandak J, Sandak A, Zitek A, Hintestoisser B, Picchi G. Development of Low-Cost Portable Spectrometers for Detection of Wood Defects. Sensors 2020;20(2):545

34. Fecht S, Vallée T, Tannert T, Fricke H. (2014) Adhesively bonded hardwood joints under room temperature and elevated temperatures. The Journal of Adhesion, 90(5-6), 401-419

35. Richter K, Steiger R. (2005) Thermal Stability of Wood‐Wood and Wood‐FRP Bonding with Polyurethane and Epoxy Adhesives. Advanced Engineering Materials, 7(5), 419-426

36. Custódio J, Broughton J, Cruz H. (2009) A review of factors influencing the durability of structural bonded timber joints. International journal of adhesion and adhesives, 29(2), 173-185

37. Śliwa-Wieczorek K, Zając B. (2021) Rigid and Flexible Double Shear Lap Adhesive Joint at Elevated Temperature -An Experimental Study. Polymers, 13(17), 2873